Colgate’s Ice Arena Shows Commitment to Athletics

“Our goal was to make this facility exciting from the moment you drive up to the entry on game day to the drop of the puck and final buzzer," says architect and principal in charge, Bill Massey

Sasaki

Sasaki

A team led by Sasaki and Hopkins Architects worked with their client at Colby College to develop an entirely new way of utilizing insulated metal panels to more efficiently and beautifully construct a new 350,000 SF Athletic Complex.

This new facility, to open in 2020, will be home to a range of program types and venues, including a field house, ice arena, fifty meter pool, gymnasium, squash courts, strength and fitness center, multipurpose spaces, locker rooms, training facilities, and offices. At this scale, even with a tight program layout, the voluminous venues and adjacent spaces require a vast area of exterior cladding to enclose.

Video by Hopkins Architects

Large programs like these can too often result in “big metal box designs,” but the design and construction team had higher aspirations for this project.

Through innovative approaches to facade design the team achieved that ideal outcome of elevated aesthetics, high performance, good value, and timely delivery—ultimately expanding the possibilities for the humble insulated metal panel, which is ubiquitous to sports facility design.

Benefits of this custom-designed approach to panel installation, include:

Together, alongside many other coordinating design decisions, this innovative approach helps set the Colby College Athletic Complex apart from similar large-volume facilities.

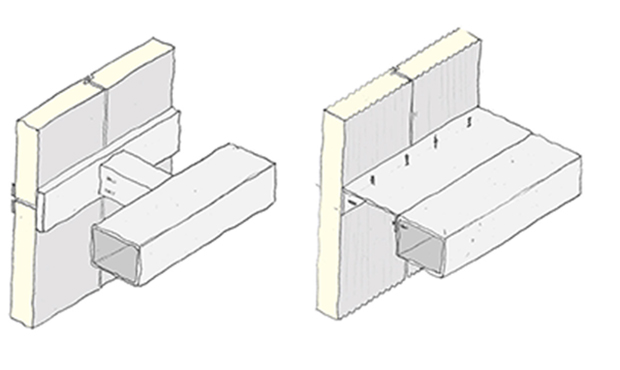

The manufacturer’s typical insulated metal panel system installation detail requires the panels to be screwed to lateral support elements, in the form of intermediate steel girts, 6’ to 8’ on center, for the height of the wall. Sasaki and Hopkins, with input from Arup, Consigli, Total Wall Systems, and Kingspan, improved upon the standard installation method by developing an innovative new way to capture the insulated metal panels by custom extrusions—similar to the manner by which glazing is captured within a curtain wall system.

Detail Axonometric Comparison of Custom vs. Standard Mounting

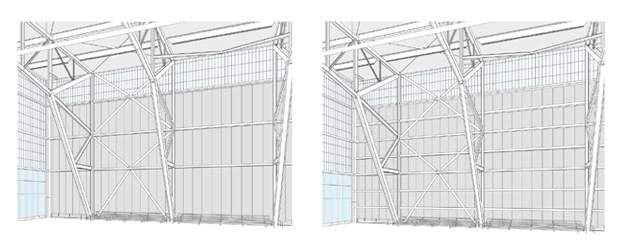

Interior Perspective Comparison of Custom vs. Standard Mounting, Figure. 1

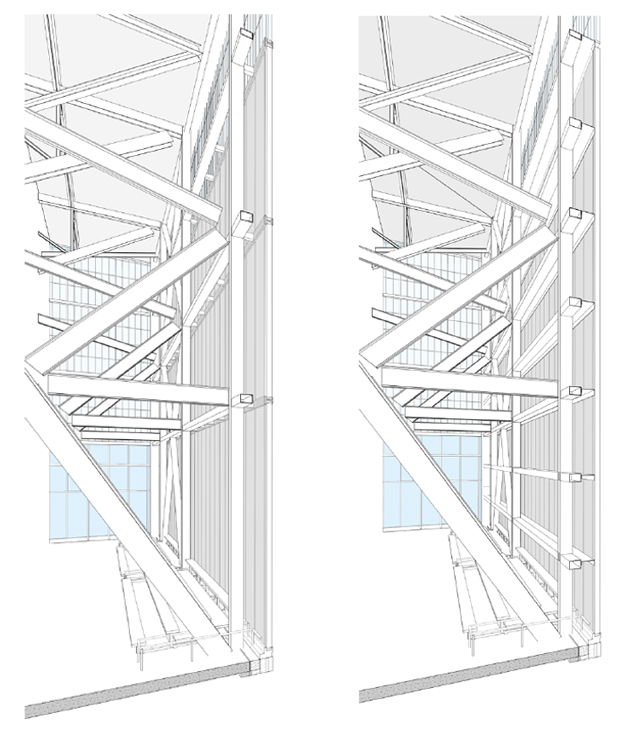

Interior Perspective Comparison of Custom vs. Standard Mounting, Figure. 2

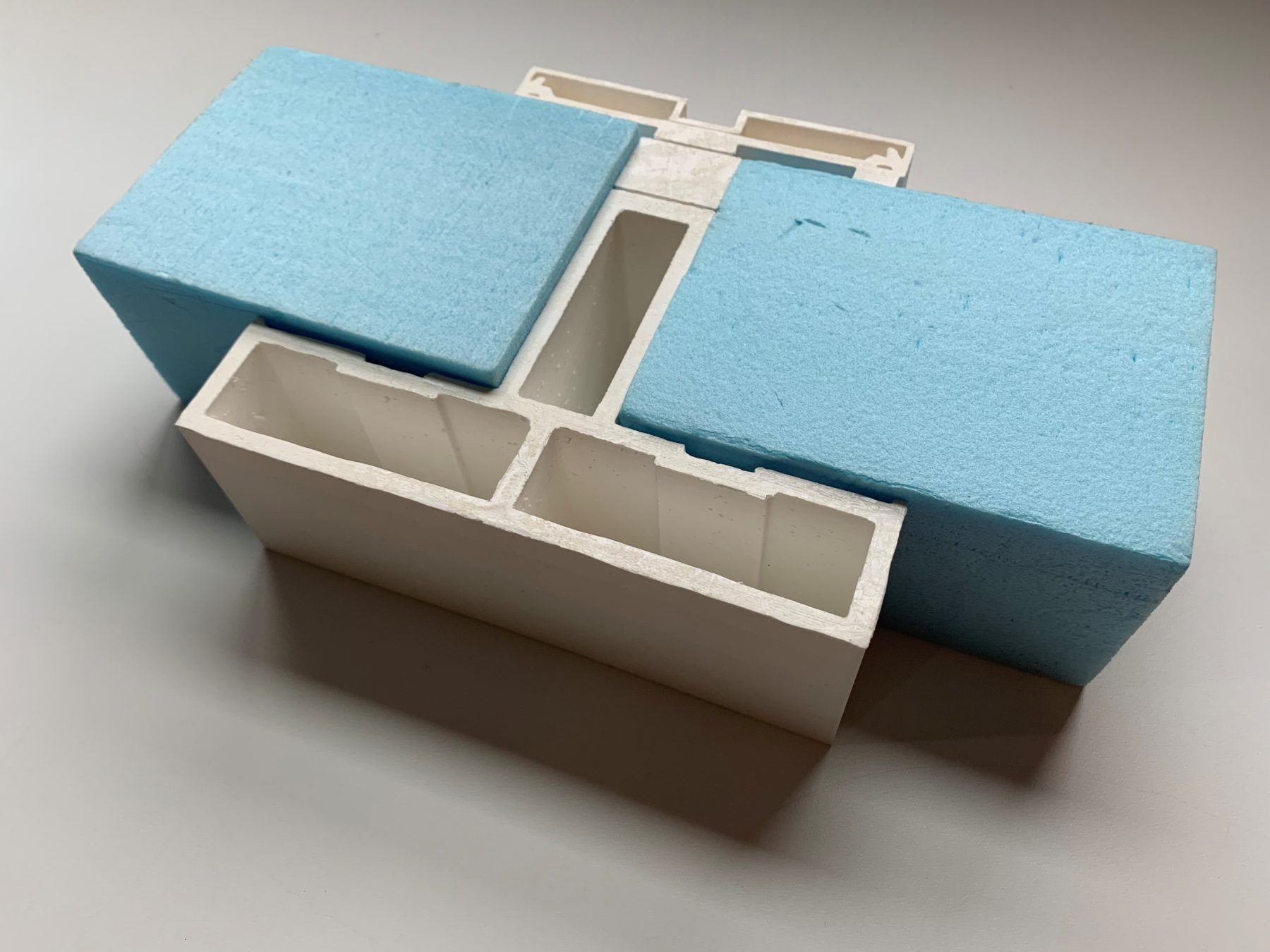

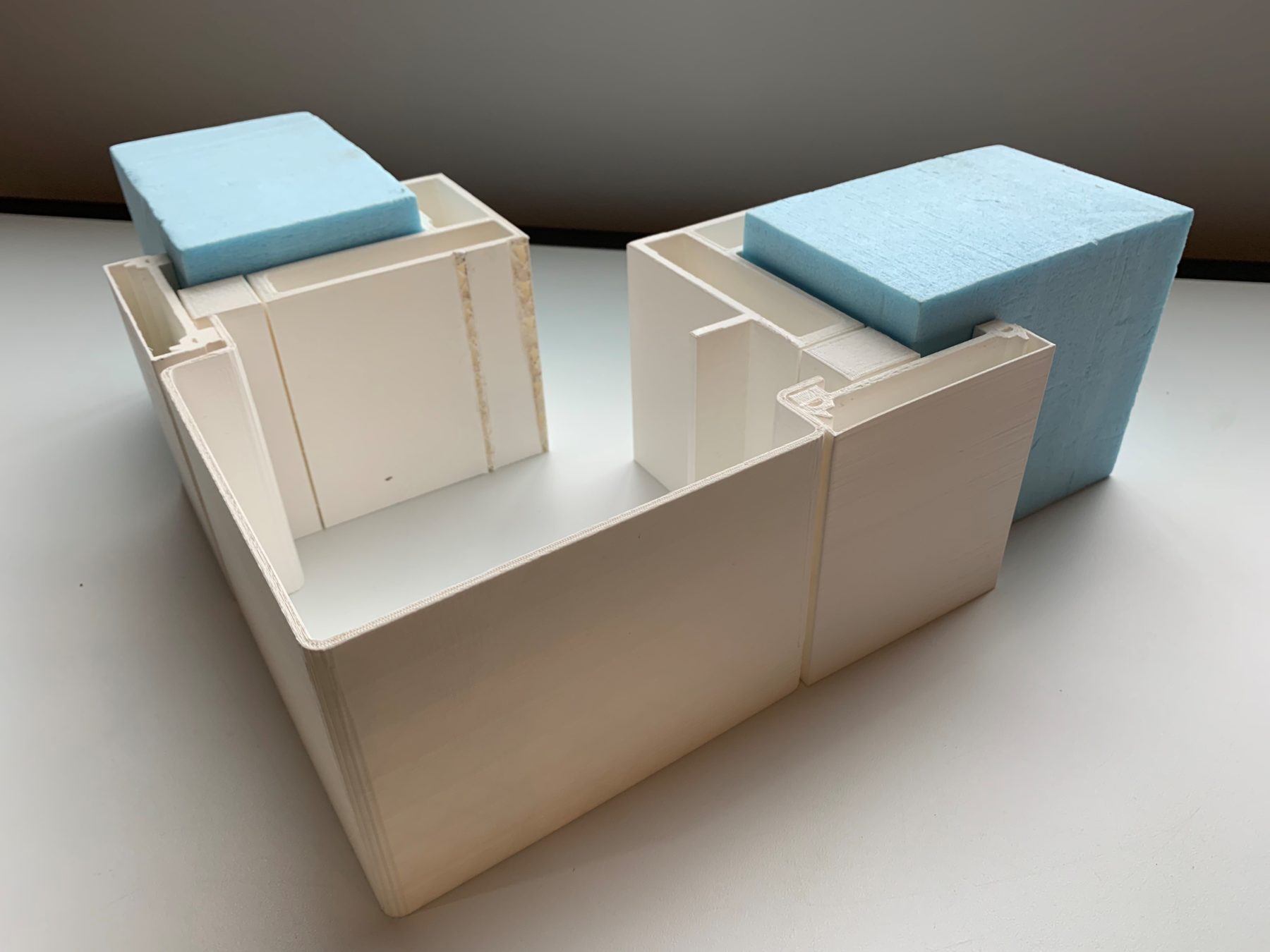

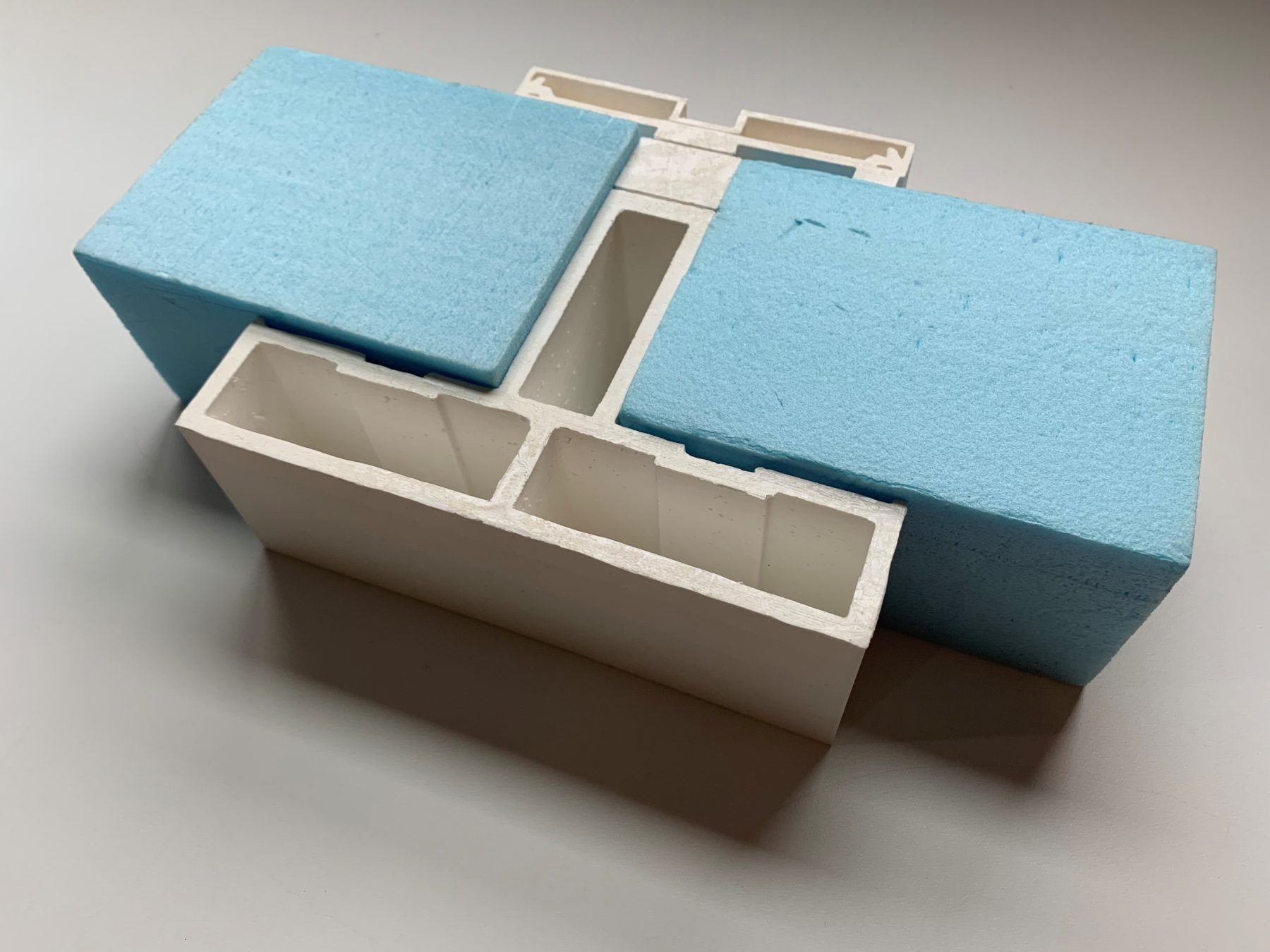

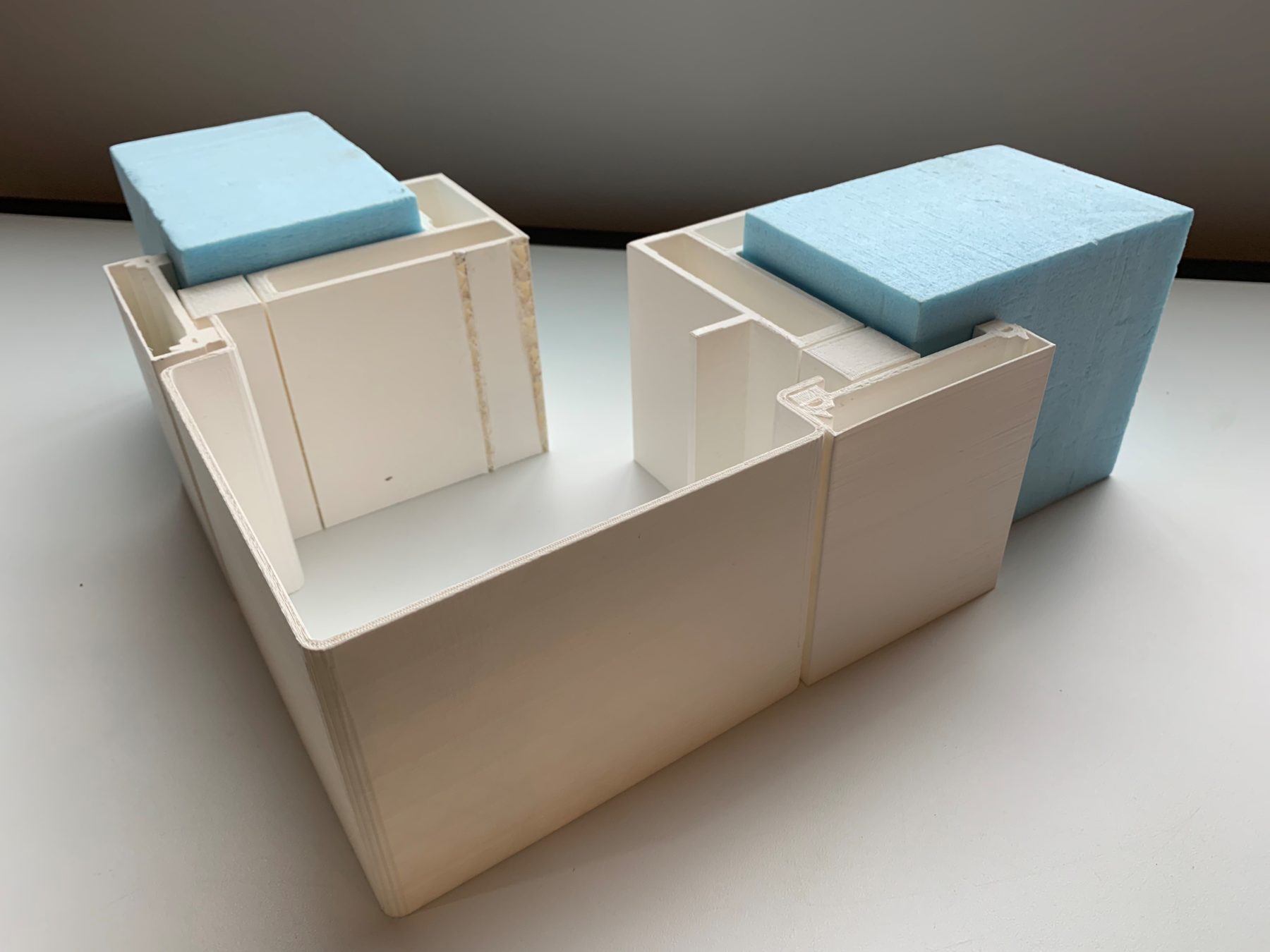

Through modeling, prototyping, custom-manufacturing, and vigorous testing, the manufacturers and construction team embraced the concept and helped to refine and execute the detail, to the ultimate delight of the client.

The new approach to installation allows horizontal datum lines to be continuously integrated throughout the entire interior and exterior design, lending subtle elegance and cohesion to the building’s expression

Colby College Athletic Complex is currently in construction and will open in 2020

At-scale models of custom extrusion developed in Sasaki’s fabrication studio

“Our goal was to make this facility exciting from the moment you drive up to the entry on game day to the drop of the puck and final buzzer," says architect and principal in charge, Bill Massey

The design of Colby College Athletics Center, a 350,000 SF new facility opening in 2020, leads in carbon reduction and cost savings for the client