Landscape Architecture Magazine (LAM) Features Permeable Pavers R&D

Researching, designing, and fabricating a permeable paver prototype to help with urban flooding

Sasaki

Sasaki

This month, Building Design + Construction (BD+C) published an in-depth article on the maker culture movement. The article, by David Malone, explores how maker culture is changing the way planning and design firms conceptualize and execute their work. Our office has incorporated the evolving tenets of this movement in many ways—from expanding our fabrication studio and training staff on machinery, to developing modular approaches to spatial planning for our clients.

Maker culture, as outlined in the article, is “the act of creating in order to get a first-hand look at the results whether, good, bad, or a bit of both.” It’s a movement all about making, fabricating, or constructing solutions to design challenges—with special emphasis placed on the process and knowledge gained along the way, rather than solely on final results.

While the ideal goal of maker efforts is that an idea becomes a successful prototype and then an actual solution for a client, the maker movement encourages failures as building blocks towards more effective solutions. “If you’re going to fail,” says Sasaki Principal Pablo Savid-Buteler, LEED AP, in the article, “you want to fail often, in pursuit of an achievement.”

Designers inspect a full-scale mock-up of a fence railing

Viewing failure as a learning opportunity is by no means a new concept—Thomas Edison reportedly tried over 1,000 different filament materials for the lightbulb before succeeding with carbon. Today, however, the desire to speed up processes often diminishes the informative time spent tinkering, failing, getting it not quite right. That’s a shame, because encouraging attention to stumbling blocks and process has impact far beyond the final design. Failing imbues humility, builds resilience, and breeds fearlessness—all of which provide the greatest opportunities for growth when coupled with honest reflection.

Brad Prestbo, AIA, CDT, CSI, Senior Associate and founding member of the Boston Society of Architects’ (BSA) MakeTANK, relates a recent stumbling block-turned-growth moment in our office:

“One of the benefits of purchasing several 3D printers for the office is that we would be able to quickly print prototypes of our designs directly from BIM software. Conceptually, this should be an easy process. But after hours of failing to develop an easy-to-use workflow, we were ready to give up. Instead, through collaborating with Sasaki Strategies, we developed a process which automatically produces a high-resolution print-ready file in minutes instead of hours by hand.”

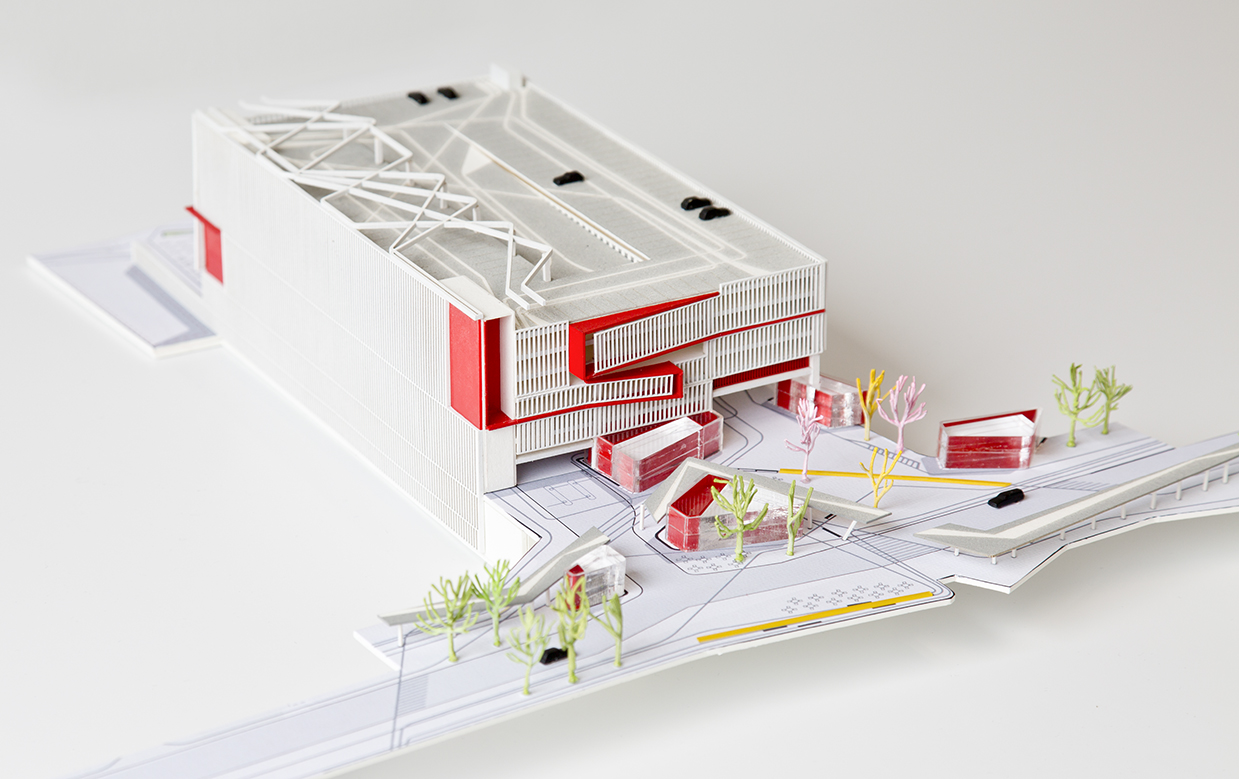

3D-printed elements enhance handmade architectural models, which help designers and clients envision a project in a high level of detail

Prestbo’s example illustrates an important synergy in maker culture. Although its outcomes are often expressed through prototyping physical objects, the digital realm is playing an increasingly central role in maker culture. Sasaki Strategies, our in-house team of mathematicians, analysts, and web and software developers, create much of the programming that enables and influences our fabrication processes.

Strategies also develops digital tools that offer solutions to planning projects. Once a robust and iterative digital tool is created, testing and retesting large numbers of possible solutions can be done with the click of a mouse. Digitized datasets reduce barriers to free-form play—allowing planners and clients to test out a continuum of options before confidently selecting the best solution for the project. As BD+C sums up “while the preliminary question is specific, the answer is open-ended.” The flexibility to test and fail, re-test and fail again, all within the low-stakes digital realm, enables the best ideas to bubble to the top.

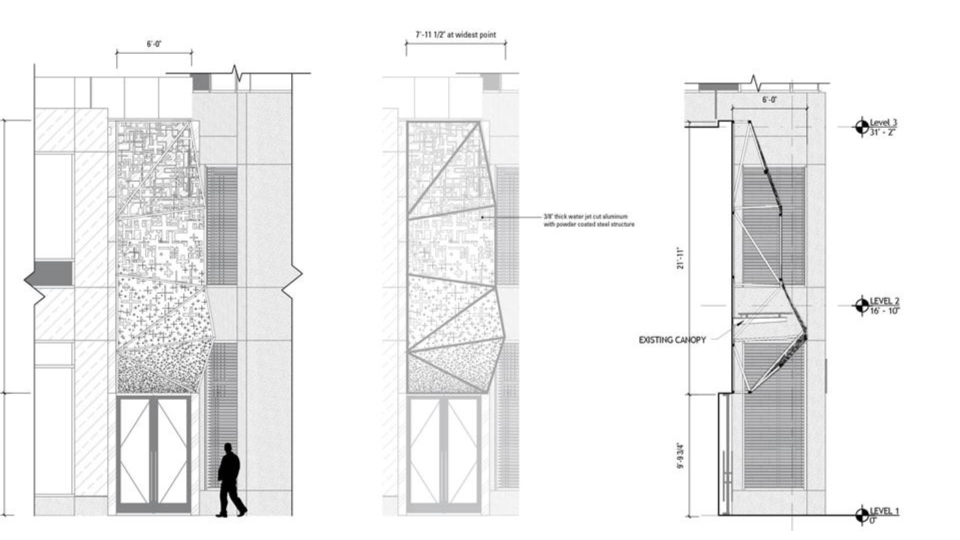

Sasaki Strategies, graphic designers, and Fab Lab experts joined forces to design a branded shade structure for Boston’s Society of Arts and Crafts

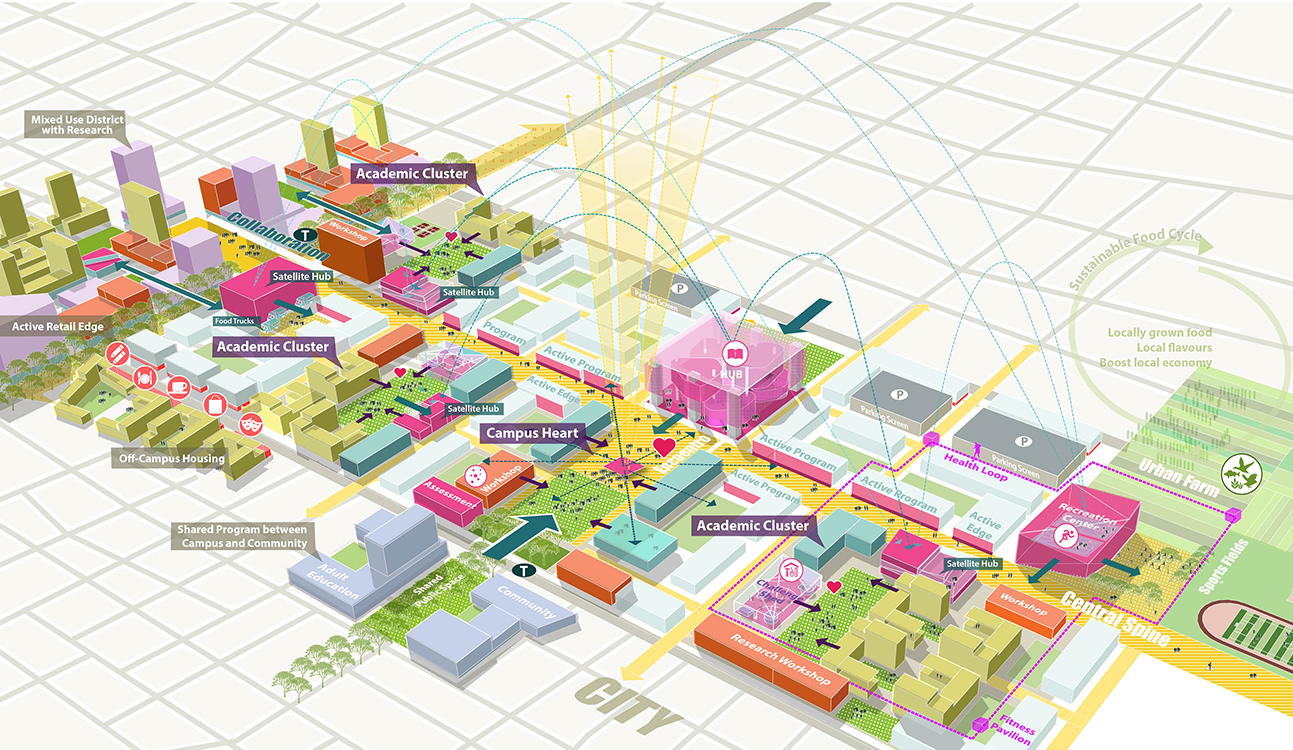

Maker culture’s dedication to process and problem-solving has bled into our planning work. The Instituto Tecnológico de Monterrey, a major university system in Mexico, tasked our planners with developing a spatial implementation of Tec 21 Educational Model—a ground-breaking pedagogical model that emphasizes solving real-world problems in a team setting. As Instituto Tec operates 31 campuses in 25 cities across Mexico, the need for a flexible approach to implementation was paramount.

“Instead of creating a master plan,” writes Malone, “Sasaki developed an entire tool kit, a catalogue of solutions, that would allow the client to combine, aggregate, and recombine the pieces in different ways to come up with solutions for a new or existing campus.” Through working with Instituto Tec, a pilot campus has been selected for rolling out this new approach to pedagogy and spatial planning.

An ideal urban campus in the Monterrey system, comprised of parts from the Tec 21 “toolkit”

Savid-Buteler explains that the process of discovery inherent to making allows Sasaki “to develop a new mindset. We find that to be very, very exciting.” Tec 21 is a great example of this shift in mindset. The Tec 21 planning team viewed the project through a prototyping lens, of designing an end-product that would be flexible and responsive to changing needs. We are excited to see how this mentality spreads further through our practice.

Designers test out bench prototypes made of high-density foam

For Prestbo, maker culture has begun to inform the basic definition of success for designers:

“The AEC industry no longer judges professional success by traditional benchmarks—the car you drive, the size of your house,” says Prestbo in BD+C. “The true measure of success boils down to this: What have you created?”

Read the article in its entirety here.

Researching, designing, and fabricating a permeable paver prototype to help with urban flooding

Exploring an installation, demonstrations, and presentations at ArchitectureBoston Expo

Thoughts on fabrication from Sasaki principals